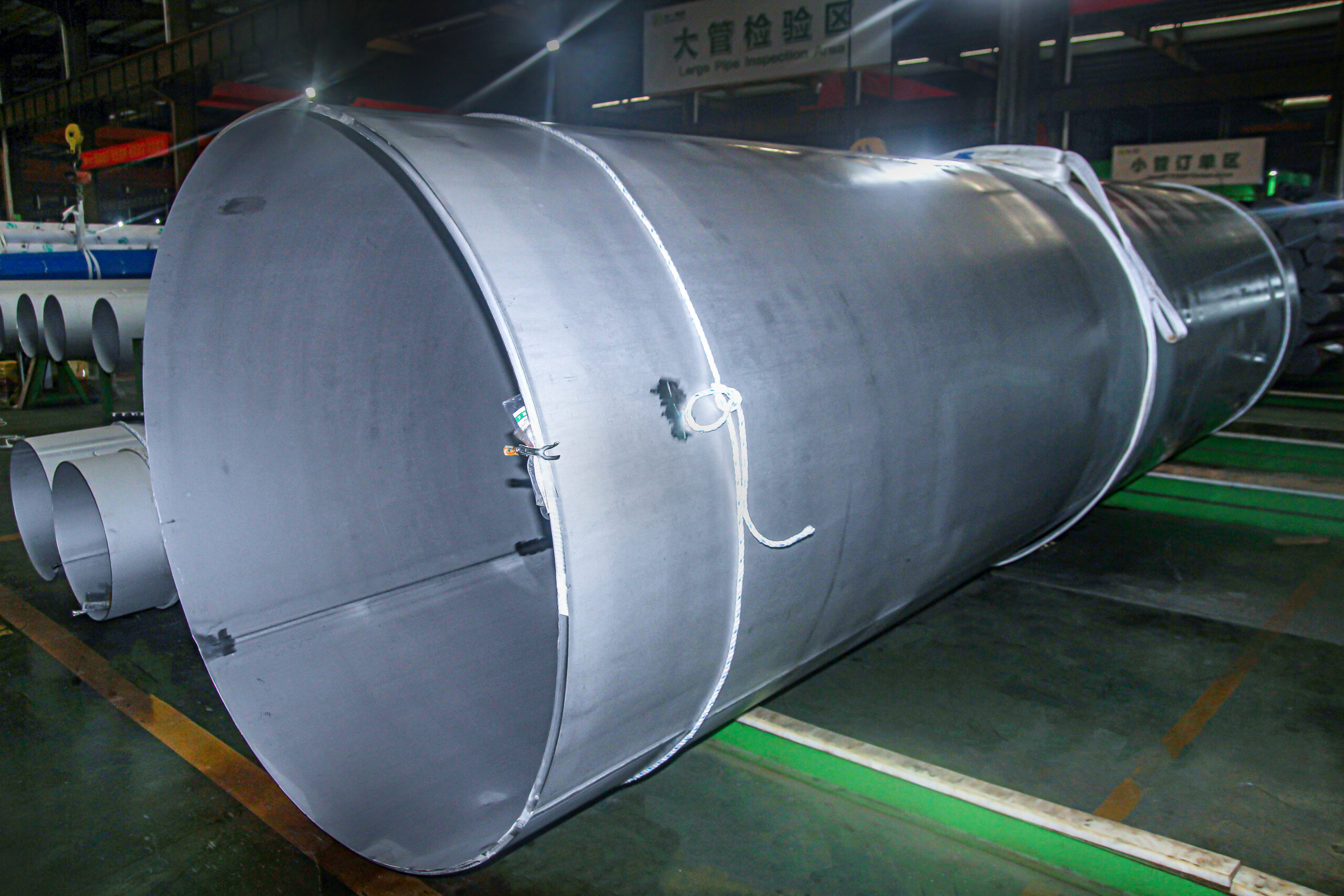

ASTM A358 LSAW Stainless Steel Pipe is a longitudinally welded stainless steel pipe manufactured by the Submerged Arc Welding (SAW) process, specifically designed for large-diameter, high-pressure, and high-temperature applications. Produced from stainless steel plates, ASTM A358 LSAW pipes offer excellent mechanical strength, superior corrosion resistance, and outstanding weld integrity, making them an ideal solution for critical industrial piping systems.

As a reliable ASTM A358 LSAW stainless steel pipe supplier, Ganyeah Group delivers pipes that fully comply with international standards and meet the stringent requirements of industries such as oil & gas, chemical processing, power generation, and water treatment.

What Is ASTM A358 Standard?

ASTM A358 / ASME SA358 is the standard specification for electric-fusion-welded austenitic chromium-nickel stainless steel pipe intended for high-temperature and general corrosive service.

Key Features of ASTM A358:

Covers large-diameter welded stainless steel pipes

Manufactured from flat-rolled stainless steel plates

Welded using automatic arc welding processes (including LSAW)

Requires radiographic or ultrasonic testing of weld seams

Suitable for pressure and non-pressure applications

Common Grades Under ASTM A358:

TP304 / TP304L

TP316 / TP316L

TP321

TP347

Other austenitic stainless steel grades upon request

LSAW Stainless Steel Pipes

Manufacturing Process – LSAW Technology

ASTM A358 LSAW stainless steel pipes are produced through a longitudinal submerged arc welding process, which includes:

1.Stainless steel plate forming (JCOE or UOE process)

2.Longitudinal welding with internal and external submerged arc welding

3.Weld seam heat treatment (if required)

4.Expansion and straightening

5.Non-destructive testing (UT / RT)

6.Dimensional inspection and pressure testing

This process ensures deep weld penetration, uniform weld quality, and excellent structural stability, especially for thick-wall and large-diameter pipes.

LSAW vs ERW Stainless Steel Pipes

Understanding the difference between LSAW and ERW stainless steel pipes helps engineers select the right product for their projects.

| Item | LSAW Stainless Steel Pipe | ERW Stainless Steel Pipe |

| Raw Material | Stainless steel plate | Stainless steel strip |

| Welding Method | Submerged Arc Welding (SAW) | Electric Resistance Welding (ERW) |

| Pipe Diameter | Large diameter | Small to medium diameter |

| Wall Thickness | Thick & heavy wall | Thin to medium wall |

| Weld Strength | Very high | Moderate |

| Typical Applications | High-pressure, heavy-duty pipelines | General industrial piping |

ASTM A358 LSAW pipes are preferred for demanding applications where strength, reliability, and safety are critical.

Product Advantages of ASTM A358 LSAW Stainless Steel Pipe

Excellent Weld Quality – Double-sided submerged arc welding ensures dense and defect-free weld seams

High Pressure Resistance – Suitable for high-pressure and high-temperature environments

Superior Corrosion Resistance – Austenitic stainless steel performs well in aggressive media

Large Diameter Capability – Ideal for large-scale pipeline and plant projects

Strict Quality Control – 100% weld inspection available

Technical Specifications

Standard: ASTM A358 / ASME SA358

Pipe Type: Longitudinal Submerged Arc Welded (LSAW)

Material Grades: TP304, TP304L, TP316, TP316L, TP321, TP347

Outside Diameter: Customized (large diameter available)

Wall Thickness: Customized according to project requirements

Length: Random length or fixed length

Surface Finish: Pickled & passivated, polished, or customized

End Type: Plain end, beveled end

Applications of ASTM A358 LSAW Stainless Steel Pipe

ASTM A358 LSAW stainless steel pipes are widely used in:

Oil & Gas transmission pipelines

Chemical and petrochemical plants

Power plants and energy projects

Water treatment and desalination systems

Industrial and process piping

Offshore and marine engineering

Why Choose Ganyeah Group?

Over 15 years of experience in stainless steel pipe manufacturing

Advanced LSAW production lines and testing facilities

Strict compliance with ASTM, ASME, EN, and ISO standards

Global export capability and stable supply

Customized solutions for large-scale and critical projects

Contact Us

Looking for a reliable ASTM A358 LSAW stainless steel pipe manufacturer or supplier?

Contact Ganyeah Group today to receive technical support, specifications, and a competitive quotation for your project.